VISUAL SIGNALING

Flashing beacons utilize glass tubes filled with xenon gas to produce a bright flash of light when energized. The technology is also used for strobe lights and flash photography.

A typical flash rate is once per second – but this can vary by device. Units with multiple flash capability offer a variety of flash sequences and rates.

Flashing beacons offer the highest degree of signaling effect and are widely used for evacuation alarms for fires, toxic gas leaks, and chemical spills; as well as for warning of moving machinery and structures such as lifting equipment, service vehicles, safety barriers, gates, and doors.

Beacon technology can influence safety

The colors mainly used in signaling technology are red, amber, yellow, green and blue, and clear/white. The range of application types includes: Alarm, High-priority warning, Low-priority warning, Inform/Indicate/Status.

Visual signals for “Alarm” and “Warning” must be perceived without fail under all circumstances. Such requirements benefit from signaling devices with the largest possible coverage area.

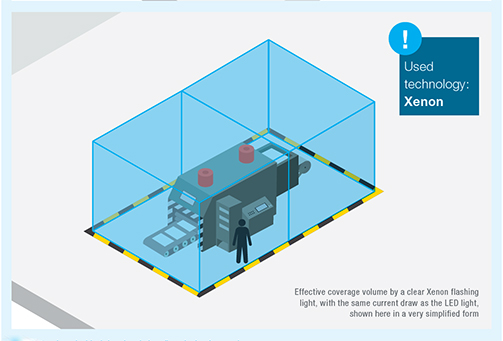

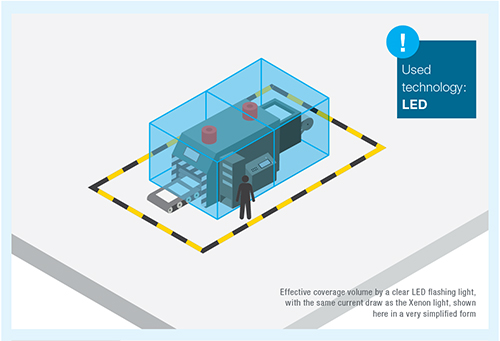

Comparison of a Xenon flashing light with an LED flashing light, both with the same current draw, demonstrates the difference the technology makes. Apart from measured signaling distance it is also important to consider the specific light emitting characteristics.

“Clear” signals were chosen for this example because they are perceived more readily at further distances.

The 3D-Coverage values are evidence that the Xenon technology offers a wider range and is more readily perceived.

The reason for this is that the Xenon flashing light emits a very short but intense pulse with a peak value far exceeding 100,000 cd. The light pulse of an LED flashing light is longer, but only reaches around 400 cd.

Furthermore, because the Xenon gas is energized in a glass tube, the light signal is emitted evenly in all directions. Conversely, the linear nature of LED light relies on reflectors and optical lenses to create an omnidirectional profile.